Picture a material that’s strong yet lightweight, functional yet artistic, and industrial yet surprisingly elegant. That’s the magic of perforated sheets. These versatile metal panels, dotted with precisely punched holes, have quietly revolutionized design across industries—from architecture to automotive, fashion to furniture. What makes them so special? It’s their ability to balance form and function in ways few other materials can.

Perforated sheets aren’t just about punching holes in metal; they’re about creating patterns that serve a purpose. Whether it’s controlling airflow, filtering light, or adding a touch of modern aesthetics, these sheets are the unsung heroes of innovative design. And with advancements in technology, perforated sheets manufacturers are pushing boundaries, offering custom patterns, sizes, and materials to fit almost any creative vision.

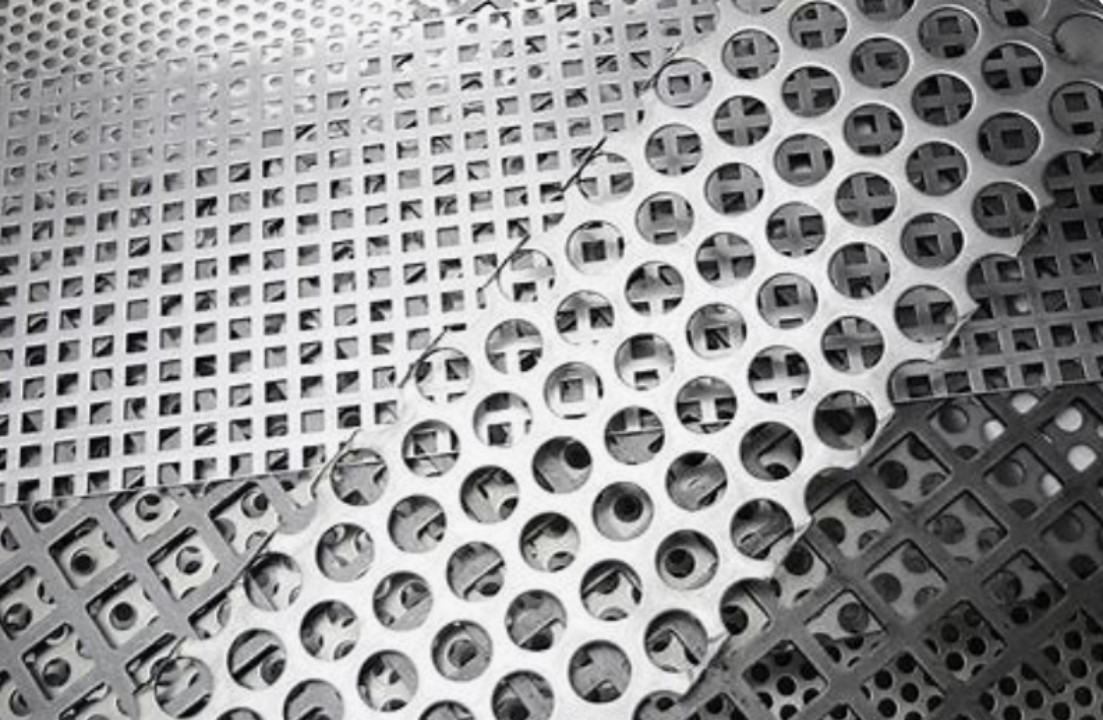

The Artistry of Perforated Patterns

One of the most captivating aspects of perforated sheets is their ability to transform rigid metal into something almost delicate. The patterns—whether geometric, organic, or abstract—turn plain surfaces into dynamic design elements. Architects love using them for fa?ades that play with light and shadow, while interior designers incorporate them as room dividers or decorative panels.

The beauty lies in the customization. Perforated sheets can be tailored to any design need—tiny holes for fine filtration, larger openings for bold visual statements, or even gradient patterns that create a sense of movement. Artists and sculptors have also embraced perforated sheets, using them to craft intricate installations that interact with their surroundings.

And let’s not forget durability. Unlike traditional decorative materials that may wear over time, perforated sheets maintain their integrity, making them perfect for both indoor and outdoor applications.

Function Meets Innovation

Beyond aesthetics, perforated sheets solve real-world problems. In industrial settings, they’re used for machinery guards, walkways, and filtration systems—thanks to their strength and breathability. The automotive industry relies on them for grilles and exhaust covers, where airflow and heat dissipation are critical.

But innovation doesn’t stop there. Acoustic engineers use perforated sheets in soundproofing panels, where the holes help absorb and diffuse noise. Even the tech industry has found uses for them, integrating perforated sheets into speaker covers and ventilation for electronics.

What’s exciting is how perforated sheets manufacturers are experimenting with new materials. Stainless steel, aluminum, copper, and even titanium are now options, each bringing unique properties like corrosion resistance, lightweight flexibility, or striking finishes.

Sustainable and Eco-Friendly Design

In an era where sustainability is key, perforated sheets shine. Their lightweight nature reduces material waste, and the holes themselves can improve energy efficiency by allowing natural ventilation, cutting down on artificial cooling needs. Architects are using them in green buildings to create passive cooling systems, while urban planners incorporate perforated sheets in sustainable infrastructure like solar panel enclosures.

Recyclability is another big win. Most perforated sheets are made from metals that can be repurposed indefinitely, making them a favorite for eco-conscious designers. Even the production process has evolved, with manufacturers adopting laser and waterjet cutting to minimize waste.

Unexpected Applications: From Fashion to Furniture

Who said perforated sheets belong only in industrial or architectural settings? Designers are taking them into unexpected territories. High-end fashion brands have experimented with perforated metal in accessories and even clothing, creating edgy, futuristic looks. Furniture makers use them for sleek, modern tables, chairs, and lighting fixtures that blend industrial chic with functionality.

In home decor, perforated sheets are showing up as backsplashes, shelving, and even artistic wall panels. Their ability to let light pass through while maintaining privacy makes them ideal for creative room partitions. The possibilities are endless—limited only by imagination.

The Future of Perforated Sheets

As technology advances, so do the applications for perforated sheets. With 3D modeling and precision cutting, custom designs are more accessible than ever. Smart cities of the future might feature perforated sheets in dynamic fa?ades that adjust to weather conditions, or in infrastructure that combines durability with aesthetic appeal.

Perforated sheets manufacturers are also exploring hybrid materials—combining metal with composites or coatings for enhanced performance. Imagine sheets that change color with temperature, or ones embedded with solar cells for energy generation. The potential is staggering.

One thing’s for sure: perforated sheets are no longer just a utilitarian material. They’ve become a canvas for innovation, a tool for sustainability, and a staple in cutting-edge design. Whether you’re an architect, engineer, artist, or just someone who appreciates smart design, there’s no denying the impact of these humble yet extraordinary panels.

So next time you walk past a striking building fa?ade, admire a sleek piece of furniture, or even notice the grille on your car, take a closer look. Chances are, perforated sheets are working their magic behind the scenes.